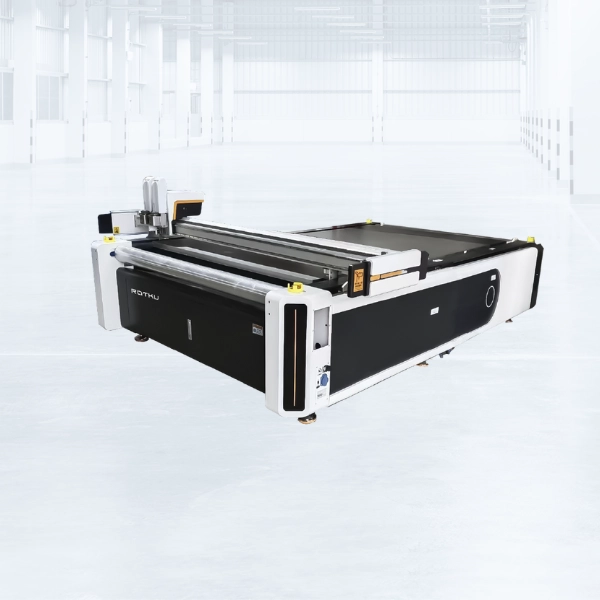

Key Features

The Rotku MC-1625 Multi-Cutter is designed to provide a versatile and efficient cutting solution for various industrial applications. With cutting-edge technology and a robust system, this machine maximizes productivity and precision, making the cutting process straightforward and reliable.

- Multiple cutting tools for different applications.

- Powerful vacuum pump that ensures perfect material holding on the worktable.

- Equipped with a large camera and projector for precise alignment.

- High-performance servo motor and controller system.

- High-quality components like the Schneider switch for stable and safe operation.

Compatible Materials

The Rotku MC-1625 is compatible with a wide range of flexible materials, such as leather, fabric, carbon fiber, PVC, foam, sponge, cardboard, and gasket materials. Additionally, with its optional milling tool, it can cut harder materials like foam PVC boards, acrylic, and wood, making it the ideal choice for workshops seeking versatility in their cutting processes.

Projects You Can Do

Solutions for a wide range of industrial applications: